Automotive

Mach FTD is a mainstream industrial solutions provider in automotive spares production (parts, components, tires) and assembly processes with a complete offer of equipment and solutions.

From economic and production perspectives, the automotive industry represents an important economic sector in Romania. The work environment is demanding for humans without the assistance of technology, as products with different characteristics go through different stages of production and preparation for delivery, which requires attention, repetitive activities and difficulty in handling.

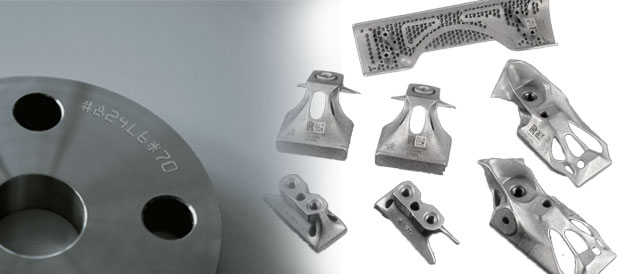

- 2D codes

- QR codes

- Complex graphics

- Small characters (from 0.9 mm)

- Large characters

Thanks to partnerships with mainstream suppliers, we apply labels on any type of product, regardless of the position of the label and the characteristics (shape, material) of the products. The size, shape and material from which the labels are made are not a challenge for us.

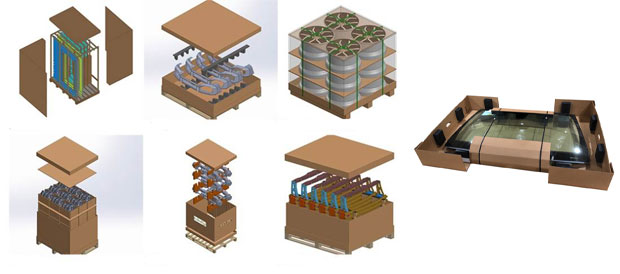

The equipment and services offered by the Packaging Division can solve any requirement both for individual products and for groups of products or bulk products. Thus, the solutions provided are dedicated to each stage of packaging, respectively primary, secondary and tertiary packaging. We pack any product to the highest quality standards regardless of shape and material.

Our solutions are suited for horizontal and vertical packaging, with stretch film, heat-shrinkable film, strap tape, in boxes or different types of packaging that can be used in the production of car components and parts.

Through the Intralogistics Division, Mach FTD can solve logistical challenges specific to automotive sector such as storage, identification, handling of small parts and preparation of the order for delivery, sorting of parts, management of very large stocks of small parts, the productivity level of employees in logistics departments in the long term, the efficiency of storage space, the palletizing of large and/or heavy components, the traceability of spare parts, etc.

Mach FTD provides complete solutions to the automotive field, among which the most requested are: storage of components and preparation of orders, quality control systems, warehouse management system (WMS), handling and transfer of small parts, sorting of spare parts through bin picking, palletizing with a robot or palletizing stations without a robot, tertiary packaging (specific packaging for order delivery) etc.

Modern and competitive solutions in the production of automotive components and spare parts, as well as in the field of automotive assembly, are offered through the Automation and Robotics Division. The modernization of production through robots and process automation offers long-term strategic advantages in terms of production efficiency and human resource management. Thus, dangerous, high-precision, or repetitive activities are successfully taken over by robots programmed not only to execute but also to "make decisions" based on the entered variables and with the help of high-precision scanners that guide them to accurately identify any characteristics of spare parts and components. A custom, highly useful solution for the automotive industry is the robotic Bin Picking cell, where you can find out more details by accessing Bin Picking by Mach FTD.