Customer Request:

The implementation of an automatic integrated transport and picking system with the existing WMS software, in order to optimize the flow, to increase the order processing capacity and to achieve the automatic replenishment.

The request has been formulated because initially, the picking was being carried out manually, by the operators, by moving the products around the entire surface of the warehouse, in order for the products to be taken over according to the received orders.

Provided Solution:

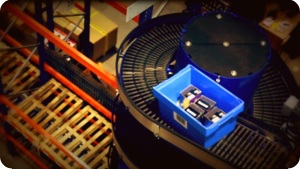

The implemented solution consisted, from the hardware’s point of view, in a number of motor driven roller or servomotors conveyors on the segments that required the accumulation of the containers locally, in a number of chain and link conveyors, on the segments that required only transportation, without accumulation and in a number of spirals for the vertical transportation, between the stories.

The system has been implemented on the existing Emag platform, consisting in 3 stories.

The plastic containers, having the dimensions of 600 x 400 x 300 mm, are being filled starting from the ground floor.

On each container two bar code labels have been applied, one on each side.

An order is being assigned to each one of the containers, as they are entering the system, and they are being filled on the chain and link conveyor, as they are being transported to the 3rd floor and further on, until the spiral for the vertical transportation, reaching the 2nd floor.

The entire system has a closed circuit, the intersection between the supply area and the recirculation area being controlled by means of a pneumatic pusher and some dynamic stoppers, in order to avoid the collision of the containers or a blocking of the intersection.

The entire system is also being used for the replenishment operation, the products being transported to the containers in order for the shelves to be refilled; the system is able to function both at the same time with the containers destined for the replenishment, as well as with the containers destined for the orders.

Results:

Besides the exponential growth of the productivity and the optimization of the operators’’ activity, the system provides the following benefits:

- The automatic management of the transport and direction of the product containers.

- The reduction of the errors to a minimum.

- The possibility to perform upgrades, due to the modular components.

- The integration with the WMS of the warehouse.

- The reduction of the human resources involved in the picking operation to a minimum.