Loading...

Intralogistics

Mach FTD is the only Romanian company specialized in complete industrial solutions and also an important integrator of personalized solutions in logistics. We offer the latest concepts, modern solutions that we have developed over the past few years for different areas, including: interoperable transport, process traceability, quality control, picking solutions, printing and labeling, packaging, marking, robotized solutions for palletizing and depalletising, pallets, pallets interchange.

Together with our specialized suppliers, we are able to offer the following types of equipment and services, used in modern logistics:

- band conveyance

- chain transport

- ascending / descending spirals

- lifts

- telescopic conveyors

- palletizing

- pallet wrapping

- strapping

- pallets interchange

Together with our specialized suppliers, we are able to offer the following types of equipment and services, used in modern logistics:

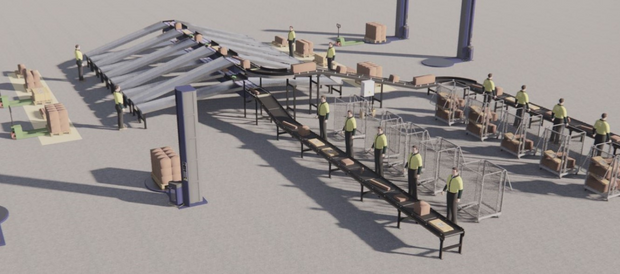

- Interoperable transport systems for the whole range of products (plastic containers, trays, cartons, etc.) including the following:

- band conveyance

- chain transport

- ascending / descending spirals

- lifts

- telescopic conveyors

- Sorting and picking solutions made with diverting and regrouping systems to perform related operations. These involve product identification, separation, collection and storage, the only manual operation being to refill the product repositories.

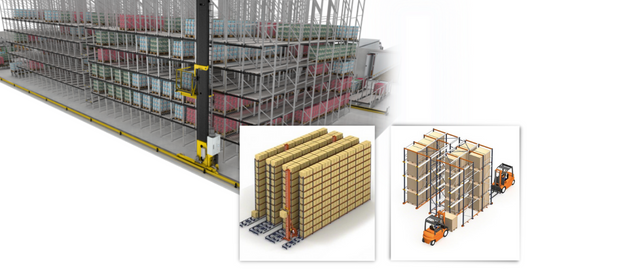

- Dynamic storage solutions that include shelves equipped with gravity transport systems in the FIFO system.

- Dynamic weighing systems - weighing products in bulk and verifying them with non-compliant line-evacuation methods, rejection control, data collection over the network.

- Streamline printing and labeling - an indispensable process in the logistics sector that underlies picking and diverting operations and the correct identification of products. A wide range of information can be printed on labels, including bar codes and 2D codes.

- Collective automatic and/or semi-automatic packaging

- palletizing

- pallet wrapping

- strapping

- pallets interchange

- General automation - IT processes and solutions - design and implementation of customized WMS applications or integration of personalized solutions into the existing WMS or ERP systems of the beneficiary (product traceability, local decision, centralized decision).

- Optimizing and automating the process of tracing production

- Remove manual operations

- Presenting specific and useful reports for the user and management level

- Exact, real-time control of operations on the production line and storage area

- Locating a product within the production stream and storage area

- Real-time knowledge of the situation in the production process and storage area

- Increasing the capacity of processing information and products

- Optimizing human resources

- Quality control