Beverages

- High-quality coding at the highest speeds

- Continuous printing capacity for 24 hours

- Excellent reliability in difficult working environments

- Equipment that meets IP standards for heavy work environments

- Laser codes remain clear and visible even after washing

- Excellent adhesion to metal

- excellent adhesion even on the wet bottle

- Non-contact laser printing will not damage the surface

- The power of the lasers can be adjusted to provide quality coding without perforating the package

Alongside the marking process, the labeling process is essential. We label any container no matter its shape, material composition, or position on the production line--all at high speeds and without stopping. There are a variety of labeling equipment options available to meet different labeling speeds, with varying costs for consumables.

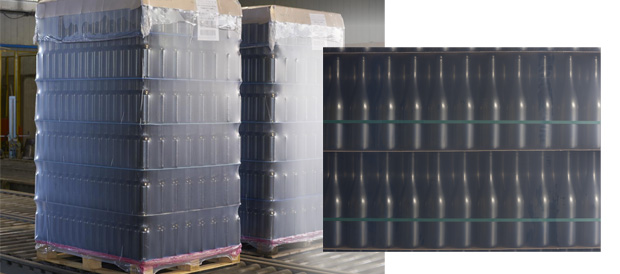

The packaging solutions that beverage producers can request from us meet all the legal requirements as well as those related to performance. For bottling lines, we offer PET-blowing machines, washing facilities, and other packaging-specific equipment.The equipment we provide includes installation, servicing, and training--all of which are available for an extended period of time. We also offer packaging modules specifically designed for beverage producers who demand high throughput rates.

For producers at the beginning of the journey, we offer turnkey solutions, such as:

- Automatic and semi-automatic equipment

- Solutions for all stages of packaging (primary, secondary, and tertiary)

- Monoblock or multiblock modules

- Palletizing stations with or without robots

- Complete packaging lines customized to the client's needs

- Dedicated installation, service and maintenance services

- Conveyors

- Sorting equipment

- Positioning equipment

- Identification and control equipment

- Cranes

- Storage equipment

- Equipment for product grouping

- AVG vehicles