Automatic palletizing line of canisters

27.05.2022

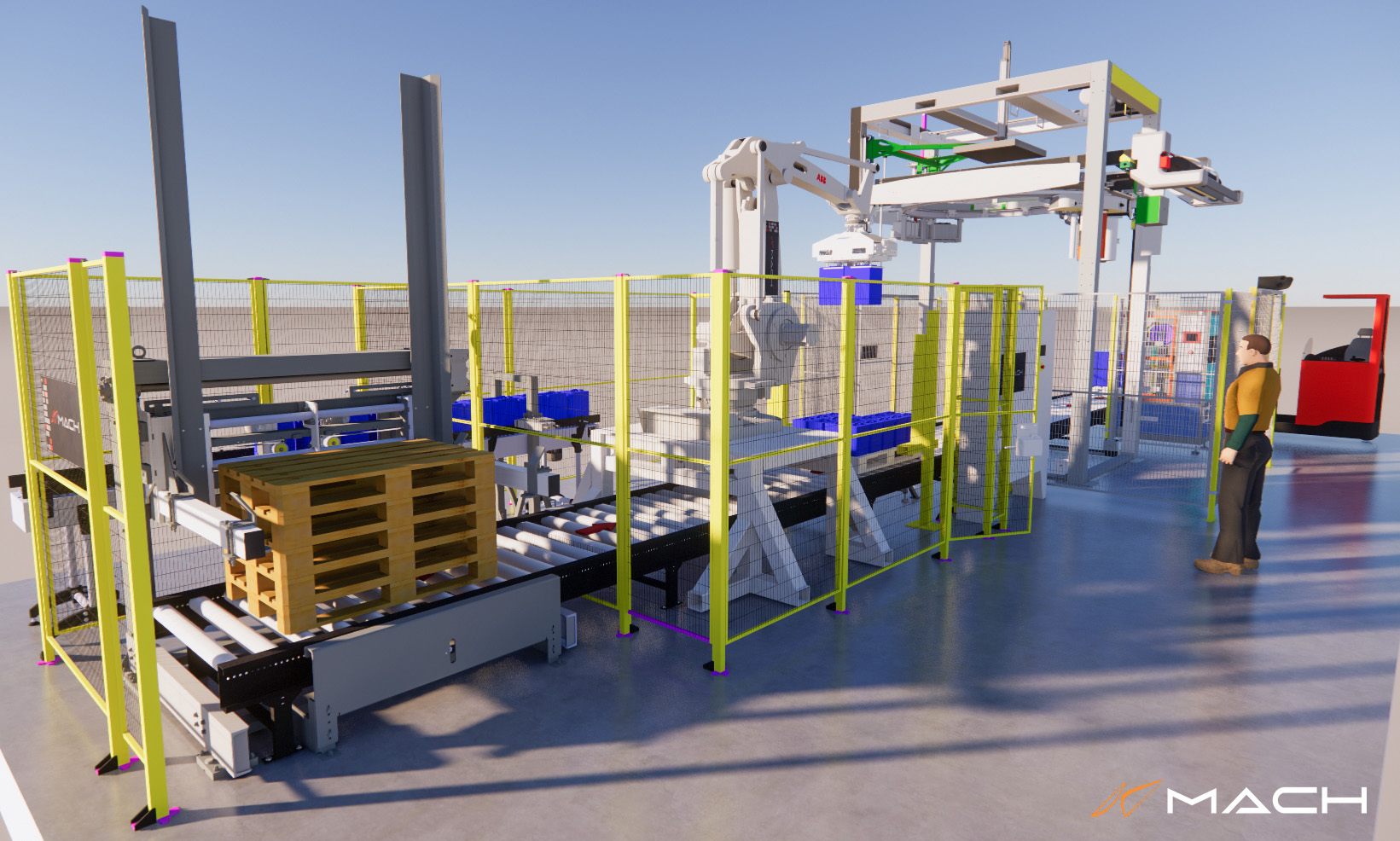

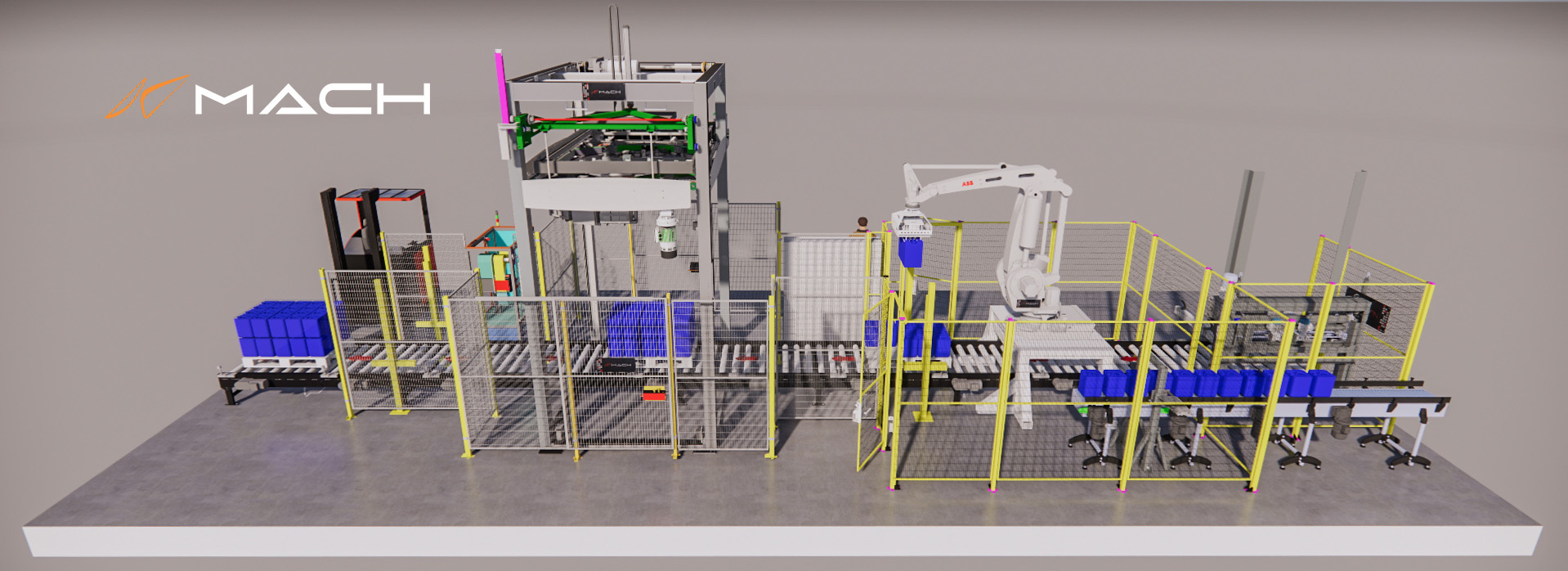

Mach FTD presents a new palletizing solution, which consists of the design, execution, and implementation of an automatic canister palletizing line.

How does it work?

The automatic canister palletizing line was created to optimize the tertiary palletizing and packaging process, and to provide a work environment suitable for the human workforce.

From the point of view of the workflow, the canisters are taken from the production line to the palletizing cell by means of a conveyor with an accumulation and centering function. After positioning the products, the robot picks the canisters, stabilizes them during handling, and places them accurately on the pallet. The precise positioning of the canisters ensures their integrity in the later transport phases.

After completing the pallet, it is transported to the packing and labeling area. An automatic stretch wrapping machine applies stretch foil to the pallet, and in the next step a print & apply labeling system applies a side label for subsequent identification and traceability of the pallet.

The packed pallets are then picked up with the forklift and transported to the storage area.

The line is operated by a PLC that can be monitored and controlled from an automation panel, designed, and built by the Mach FTD team. It is equipped with an HMI screen for user interface, acoustic and light signaling to warn the status of the system, a general ON / OFF button, Start / Stop button, indicator lights for the presence of supply voltages, a button for emergency stop, inverters for motor control, and so on. All motors and sources are protected from overload and short circuits, and any interaction with the security system will instantly stop the operation of the area.

A priority goal in the design and implementation of the system was to ensure the highest safety conditions at work. The components of this line are composed of standard equipment, as well as specific modules designed and manufactured by Mach FTD

- Product conveyors

- Pallet conveyors

- ABB IRB 660 robot

- Electro-mechanical gripper - designed and manufactured by Mach FTD

- Robot support chassis - made by Mach FTD

- Automatic pallet destacker - designed and manufactured by Mach FTD

- Robopac pallet stretch wrapping

- Label applicator for pallets Altech Alcode P

- Troax safety fences

- General automation panel - designed and built by Mach FTD

How can this help you?

The automatic palletizing and tertiary packaging line for pallets represents a very useful solution in factories where:

- The workload in the palletizing area is high and is performed in difficult conditions for humans (heavyweights).

- The activities are repetitive and pose a risk to the health of employees.

- There is already a production line that is not complete in terms of palletizing and pallet wrapping processes.

- There are capacity and quality requirements that cannot be ensured by manual processing.

- An increase in production is planned for which optimizations are needed in the production processes and preparation of products for delivery.

Services offered in the package

This is not only an efficient solution from Mach but also comes with the right complementary services that our customers have come to expect from us.

- The design of the line, its realization, and the implementation are executed entirely by Mach FTD.

- The offer includes post-installation services, such as monitoring, maintenance, service, instruction for using the line for operators, and manual for operating the line.